The term medical device is vast and applies to a lot of things. From huge MRI machines, to pacemakers for weak hearts, to surgery equipment, and even mechanical organs. All of it falls under the umbrella of a medical device.

The FDA describes medical devices as “any type of machine, instrument, equipment, device, or delivery system that is involved with or used for any type of medical purpose or application, with the intention to affect the body in a non-chemical manner.”

Conceptualization and ideation

Manufacturing medical devices is a complex and iterative process encompassing several crucial stages. It starts with the conceptualization and ideation stage, where both manufacturing and medical knowledge play a key role. This stage requires extensive collaboration between engineers, scientists, and healthcare professionals, as they translate new medical ideas or processes into viable and functioning products.

Research and development

The R&D doesn’t just stop at the conceptualization phase. Determining the feasibility and need for the medical device in focus is as important as the medical need for it. Manufacturers also need to know if the device is capable of handling the dynamic conditions of the procedure. This will help them know if doctors can rely on its consistency.

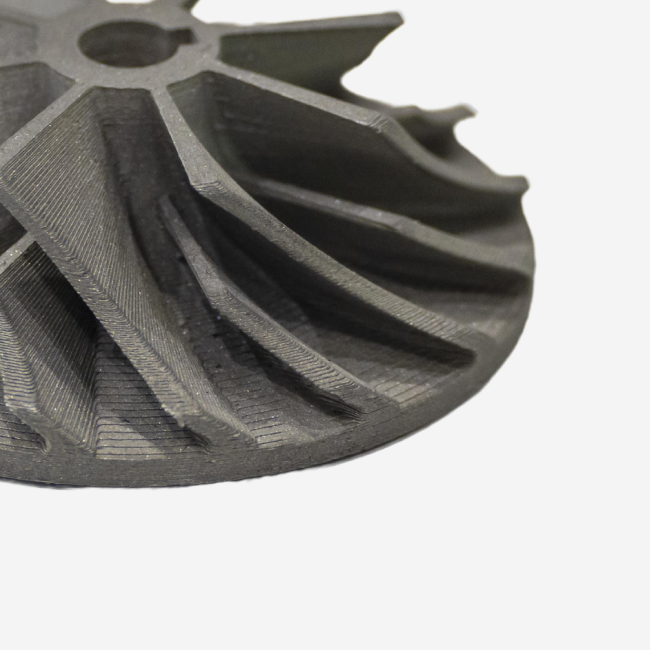

Prototyping and testing

This stage often involves prototyping and testing to validate the design, functionality, and safety of the device. Iterative design refinement based on user feedback is crucial for optimizing usability and performance and become even more integral for healthcare applications.

Design control and risk management

Another crucial area in this phase is risk management. Manufacturers are responsible for establishing design controls to ensure adherence to the quality and safety requirements throughout the process.

Human bodies are unpredictable and so is the medical field. Thorough risk assessment and mitigation strategies identify and address potential hazards associated with the device and help doctors make informed decisions for their patients.

The associated risks are dependent on the kind of medical device as well. Surgical instruments or some other tools will not go through as many tests or trial runs. That’s because its applications are relatively simple and the control is still in the hands of the doctor.

On the other hand, advanced surgical robots, replacement organs, or any other complex implants will go through extensive testing and documentation to mitigate all sorts of risks. From running simulations to conducting trials on actual patients under controlled conditions.

Healthcare businesses often need to coordinate closely with healthcare professionals and ensure that they cover every scenario before the product is released in the market.